|

|

|

|

|

| Author |

Message |

Isnochys79

Community Member

Joined: 17 Jan 2013

Posts: 121

Location: France

|

Posted: Wed Jun 17, 2015 11:57 am Post subject: What's the story Mother ? Seat and console project Posted: Wed Jun 17, 2015 11:57 am Post subject: What's the story Mother ? Seat and console project |

|

|

Hello guys,

Would you mind me to let you know about my Nostromobsession or Nostromania... again !!

Back on the bridge. My first idea was to recreate the mother room from my beloved cardboard sheets and in the continuity of my previous model.But when I realised that I had to create all the tiny lights and the such specific walls design, I feel unable to do that at such a small scale and in cardboard.

So I start thinking at a larger model of the seat and the console only, which could fit with the upcoming (one day maybe) 1/6 Ripley figure from Hot Toys…

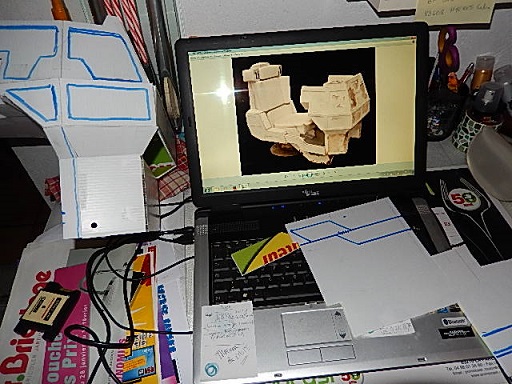

After some sketches from the photos published here on PS and help from Ads1066 for the main measures, I have decided to built a quick pre-model, from easy cuttable plastic sheet, to help me thinking in 3D.

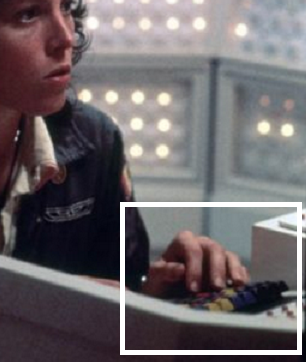

So I started deducting all measures from the Tom Skeritt's body proportions on this photo.

And here is the plastic model almost completed…

…and that's the exact moment when,considering this model, I have thought : "If it was only six times bigger, I could sit in it !".

Well, well, well... I had to give up carboard and think plywood and chipboard, a new experience for me, but suddenly, I get really enthousiastic about recreating these props at real size !

The first step had to be considered as a test. If I could cut,quite easily from chipboard, one of the most irregular part of the seat I could make all the others, because more simple shapes (well at that time it seemed more simple).

So I started with the "legs" because they determine too, the seat and console widths…

I was quite satisfied with these first cuttings (two chipboard layers for each leg) so I can start the project. But I realise that, at full scale, these two props only , may need as much time as my whole cardboard bridge...and I hope less than the Nostromo model !

I hope that you will be interested in my upcoming progress in the following weeks (months ??) and here is my last one :

(For "easy" transport and storage, these props have to be separable, the "hole" seen in the armrest is intend to receive,later, the removable side junctions with the console)...

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

joberg

Community Member

.jpg)

Joined: 06 Oct 2008

Posts: 9466

|

Posted: Wed Jun 17, 2015 7:13 pm Post subject: Posted: Wed Jun 17, 2015 7:13 pm Post subject: |

|

|

Wow, you're really going all out on that one! Anticipating the rest with much impatience  |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Buch

Community Member

Joined: 27 Feb 2014

Posts: 1184

Location: Copenhagen, Denmark

|

Posted: Thu Jun 18, 2015 1:36 am Post subject: Posted: Thu Jun 18, 2015 1:36 am Post subject: |

|

|

Interesting project

_________________

Monsieur, azonnal kövessen engem bitte |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

retrogarde

Community Member

Joined: 29 Dec 2012

Posts: 131

Location: Maine

|

Posted: Tue Jun 23, 2015 7:55 am Post subject: Posted: Tue Jun 23, 2015 7:55 am Post subject: |

|

|

| Awesome project! Compared to the chair the rest of the room would be a piece of cake. Good luck man! |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Isnochys79

Community Member

Joined: 17 Jan 2013

Posts: 121

Location: France

|

Posted: Fri Jul 03, 2015 7:29 am Post subject: Posted: Fri Jul 03, 2015 7:29 am Post subject: |

|

|

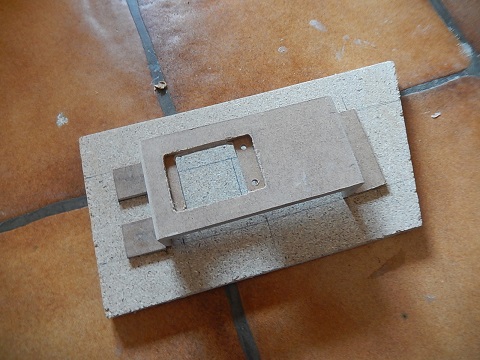

Thank you for your encouragements guys. I have now realised how many time it's take to work with chipboard.Cutting, sanding and adjusting parts together are so laborious and currently hot temperatures here, in south of France don't help

My last progress are on seatback and basis :

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

joberg

Community Member

.jpg)

Joined: 06 Oct 2008

Posts: 9466

|

Posted: Fri Jul 03, 2015 9:14 am Post subject: Posted: Fri Jul 03, 2015 9:14 am Post subject: |

|

|

Chip board is known in the business as "Beaver Barf" (or in French: Vomi de Castor)  Difficult to work with and not really sturdy. Difficult to work with and not really sturdy.

Do you have MDF in Southern France? And if yes, your construction will be sturdier and will last a long time.

Bonne chance.  |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Isnochys79

Community Member

Joined: 17 Jan 2013

Posts: 121

Location: France

|

Posted: Mon Jul 20, 2015 3:53 am Post subject: Posted: Mon Jul 20, 2015 3:53 am Post subject: |

|

|

Thank you Joberg. Yes we have MDF but more expensive... and I have already bought the "beaver barf" (funny and scary name) lot for the prop

but hank you for your advice.

My last progress are about the console.

I can start the construction because I have the seat legs as reference for the width.

But even with a pre model some adjustement difficulties occur when working with wood. Really upsetting... but no choice I have to find solution to go on.

The console have some really particular parts which have to be adjusted on both sides but with two different angles !

.png)

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Isnochys79

Community Member

Joined: 17 Jan 2013

Posts: 121

Location: France

|

Posted: Fri Jul 31, 2015 6:45 am Post subject: Posted: Fri Jul 31, 2015 6:45 am Post subject: |

|

|

Slow progress... but progress  I am now working on the I am now working on the

back and upper part of the seat :

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

joberg

Community Member

.jpg)

Joined: 06 Oct 2008

Posts: 9466

|

Posted: Fri Jul 31, 2015 8:46 am Post subject: Posted: Fri Jul 31, 2015 8:46 am Post subject: |

|

|

Looking good...are you using white glue? It helps with the construction and the sturdiness of it. Also, put glue on your screws (helps a lot to make it even more solid).  |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

8th_Passenger

Community Member

Joined: 28 Nov 2009

Posts: 443

Location: Hertfordshire, UK

|

Posted: Sat Aug 01, 2015 4:33 pm Post subject: Posted: Sat Aug 01, 2015 4:33 pm Post subject: |

|

|

Isnochys79 I'm really liking your console/chair build.

I see you have built it over a chair! Are you planning on replacing the chair with some welded steel work? The whole structure must be getting very heavy now

What are your plans for the keyboard?

Looking forward to seeing it progress further.

Colin

_________________

Ripley: What's it key on?

Ash: Micro changes in air density. |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Isnochys79

Community Member

Joined: 17 Jan 2013

Posts: 121

Location: France

|

Posted: Mon Aug 03, 2015 5:59 am Post subject: Posted: Mon Aug 03, 2015 5:59 am Post subject: |

|

|

Yes Joberg I use white glue but mainly screws, thank you for the advice I will follow it.

Thank you for your interest Colin.With my "beaver barf", I feel so far from your props extreme work.

At the moment, I have absolutely no idea about the seat final support.

Now it's on a paint can... As I don't know how to steel work I was thinking at large wheel rim,maybe ?

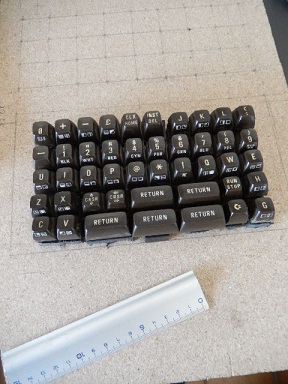

About the keyboard, I was unable to find the one used in the movie.

It seems that it was a colored one before the white paint

I have found a vintage C64 keyboard that I will use.

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

joberg

Community Member

.jpg)

Joined: 06 Oct 2008

Posts: 9466

|

Posted: Mon Aug 03, 2015 8:17 am Post subject: Posted: Mon Aug 03, 2015 8:17 am Post subject: |

|

|

Good, because as you might know, chairs are subjected to tremendous forces. Just the pressure from your back when your feet are on the ground, for example, is hard on the wood. So the movement of sitting down and getting up is putting your chair into a work-out so to speak.

That's why gluing all of the parts is important. The glue on the screw will also "lock" the screw in so there's less torsion exerted on the whole construction. |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Praxis_Effect

Community Member

Joined: 02 Aug 2015

Posts: 21

Location: Canada

|

Posted: Fri Aug 07, 2015 1:21 pm Post subject: Posted: Fri Aug 07, 2015 1:21 pm Post subject: |

|

|

Pretty neat project..!

"Engineered" building materials are a good economical solution for home projects.

They have a weakness in that they don't hold screws in the "end grain", and tend to loosen over time.

Joberg's suggestion to put glue on the screws is a great idea.

Additionally, you can also get screws specially made for particle board.

Might I also suggest "construction adhesive"?

You can get it in large tubes that go in a caulking gun. I've glued timbers to steel beams with this stuff.

It's economical and easy to use.... you can glue up all of your joints with it... or even make "fillets" along joints that you've already assembled.

Look for "PL Premium", or Lepage's "No More Nails".

How will you finish the chair?

If you're good with fiberglass and resin, it would look great... but it's smelly and messy, I think...

Looking forward with excitement..!

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Isnochys79

Community Member

Joined: 17 Jan 2013

Posts: 121

Location: France

|

Posted: Mon Aug 24, 2015 1:19 am Post subject: Posted: Mon Aug 24, 2015 1:19 am Post subject: |

|

|

Well, I have to admit that I didn't think at forces and pressure as you describe Joberg. But the seat seems really solid as I test to seat on it. My only "fear" is about the empty paint can I am using as base at the moment.

Thank you for your suggestion Praxis_Effect, unfortunately I don't know anything about fiberglass and resin. But I will try to get the best possible finitions from wood.

I am now progressing on the console upper parts. It's getting heavy and I think that I will have to add feet to the console.

.png)

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

joberg

Community Member

.jpg)

Joined: 06 Oct 2008

Posts: 9466

|

Posted: Mon Aug 24, 2015 7:03 pm Post subject: Posted: Mon Aug 24, 2015 7:03 pm Post subject: |

|

|

Inner structure (pieces of wood that you put inside the main structure) can be hollowed by simply drilling big holes into them. It'll make your construction lighter but as solid as if these pieces were whole.

You always have to count on the overall weight of your build...but it's looking good so far.  |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

8th_Passenger

Community Member

Joined: 28 Nov 2009

Posts: 443

Location: Hertfordshire, UK

|

Posted: Wed Aug 26, 2015 1:38 pm Post subject: Posted: Wed Aug 26, 2015 1:38 pm Post subject: |

|

|

Looking good Isnochys79.

Colin

_________________

Ripley: What's it key on?

Ash: Micro changes in air density. |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Isnochys79

Community Member

Joined: 17 Jan 2013

Posts: 121

Location: France

|

Posted: Fri Sep 04, 2015 8:29 am Post subject: Posted: Fri Sep 04, 2015 8:29 am Post subject: |

|

|

Now close to complete the prop  I have some days off and I can work on it at almost full time. I want it to be completed on Thurday 10th as I am going back to work the day after. I have some days off and I can work on it at almost full time. I want it to be completed on Thurday 10th as I am going back to work the day after.

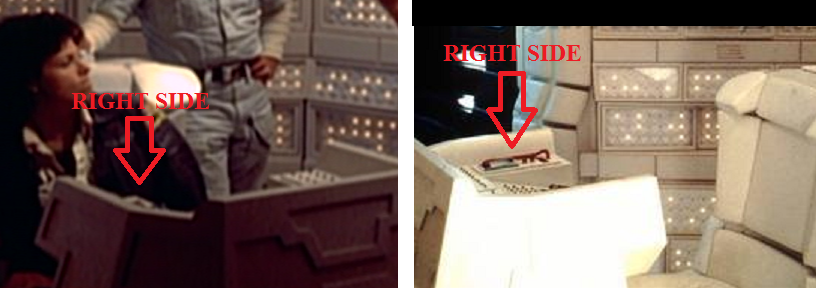

Here are some of the "fun" things I have made lately :

Cutting a C64 keyboard in order to make it look that the one in the movie...

Drilling many holes for the tiny colored lights...

Making strange panels as I was unable to find that kind of parts in everyday life

Locating correctly a panel... right or left ?...

and now starting to combine the different parts...

I really hope to be able to show you the final result on thurday. It's really the best time when you know that yout project is almost achieved and ready to be shared

|

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

Noeland

Community Guide

Joined: 24 Oct 2006

Posts: 1328

|

Posted: Fri Sep 04, 2015 10:51 am Post subject: Posted: Fri Sep 04, 2015 10:51 am Post subject: |

|

|

CRAZY cool build. I have nothing to add but admiration and awe.

And thank you for sharing build pictures. Very inspiring work.

_________________

I don't have enough blasters! |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

8th_Passenger

Community Member

Joined: 28 Nov 2009

Posts: 443

Location: Hertfordshire, UK

|

Posted: Fri Sep 04, 2015 2:15 pm Post subject: Posted: Fri Sep 04, 2015 2:15 pm Post subject: |

|

|

Great Update Isnochys79.

_________________

Ripley: What's it key on?

Ash: Micro changes in air density. |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

| Author |

Message |

joberg

Community Member

.jpg)

Joined: 06 Oct 2008

Posts: 9466

|

Posted: Sun Sep 06, 2015 8:42 am Post subject: Posted: Sun Sep 06, 2015 8:42 am Post subject: |

|

|

| Loved what you did with that keyboard! Are you going to cover the seat with "Simili cuir", vinyl or other material? |

|

| Back to top |

|

|

|

|

|

|

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

|

|

|

|

|

|

|

|